5.1 What are Pneumatics?

Originally discovered by the ancient Greeks, pneumatics is the study of air pressure. Pneumatics is a branch of fluid power that uses compressed air to power actuators. Pneumatic actuators are used to move mechanical parts, such as valves, cylinders, and other devices. Pneumatic systems are used in a wide variety of applications, including robotics, manufacturing, and construction.

In FRC teams typically use cylinders to extend and retract a piston. This can be used to move a mechanism in a linear direction, or to rotate a mechanism. Cylinders are usually measured by the stroke length, bore diameter, and rod diameter. The stroke length is the distance the piston can travel in one direction. The bore diameter is the diameter of the cylinder. The rod diameter is the diameter of the piston. The bore and rod diameters are usually the same. They can also come in a large variety of sizes and styles.

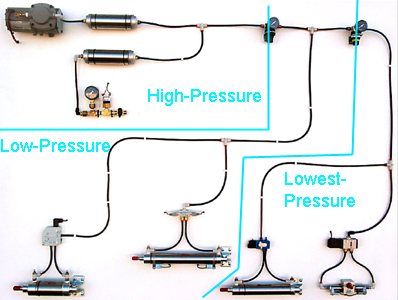

A typical pneumatic system in FRC can look something like this:

Image courtesy of FRC 358

Image courtesy of FRC 358

Below is a downloadable copy of FIRST’s pneumatics guide. This guide is a great resource for learning about pneumatics. It covers the latest hardware changes, and includes a lot of useful information. I highly recommend reading this guide.